Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

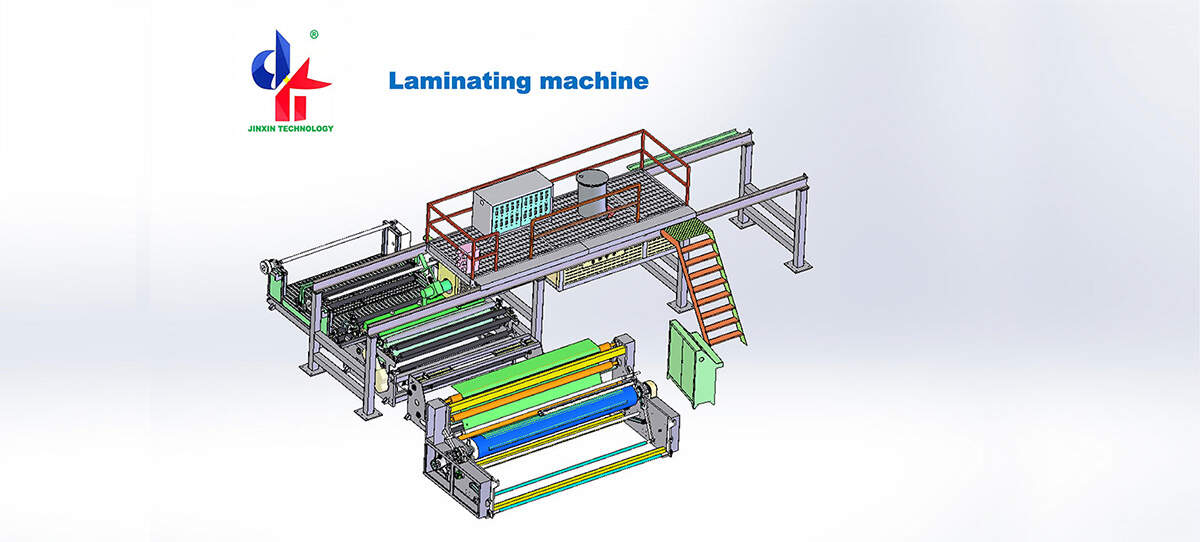

Full Automatic Best Price and Hot Selling Non Woven Fabric Coating Lamination Plant Machine From China

The main objective of businesses that produce nonwoven laminates is to increase production speed while maintaining the caliber of the finished product and the reels that hold it. This calls for a machine that will let you manage the web tension and speed during the entire operation.

| Model | JX-laminating machine | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 12*10*3.5m | 12*12*3.5m | 12*16*4.5m |

| Mechanical Speed | 200m/min | 200m/min | 150m/min |

| Thickness | 0.01~0.1 mm | 0.01~0.1 mm | 0.01~0.1 mm |

| Daily Output | 2-3T/Day | 3-4.5T/Day | 4-5.5T/Day |

| Transformer Capacity | ≈80KVA | ≈120KVA | ≈180KVA |

| Power Consumption | 520°-650°Ton | 520°-650°Ton | 520°-650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

What our Lamination Machine can do for you?

The primary goal of companies manufacturing nonwoven laminates is to reach the highest production speed possible without compromising the quality of the final product or the final product reels. This requires a machine that will allow you to control the web tension and speed at every single stage of the process.

1.PROVIDE A TURNKEY SOLUTION FOR ALL YOUR NEEDS

The Lamination Machine is a complete turnkey solution for adhesive, thermal, or ultrasonic lamination ideal for the manufacturing of hygiene, medical, filtration, and roofing products. The system includes:

Unwind stand

Laminating station

In-line slitting winder

The solution also includes the following optional add-ons:

Web accumulation system

Trim and dust suction system

DMS (Defect Management System)

In-line printing unit

Master roll and finished reel handling system

2.GUARANTEE QUALITY CONTROL WITH REAL-TIME DATA ANALYSIS

The machines use sensor technology, combined with cloud capabilities and a software platform to collect, transmit and analyze data from the production line in real-time.

Data can be collected on machine conditions that are not visible to the naked eye, allowing small variations in speed, tension, and product quality to be detected during operation, minimizing human error throughout the process. What this means is that you will have the ability to detect defects in real-time so you can make manual or automatic adjustments on the fly to obtain finished product reels free of defects and ready for shipment.

3.AUTOMATE PRODUCTION PROCESSES

The automation of once tedious and physically demanding tasks includes the loading of the master rolls at process entry, management of the shafts and the finished rolls at process exit, and the packaging and handling of the finished product using AGVs. Automation also offers several distinct technological advantages:

Dedicated web tension control at every stage along the production line to reduce defects in the final product. This allows tension to be controlled as the individual layers are unwound and moved toward the lamination machine and as the composite moves toward the slitting section and winding machine.

Full control of the machine speed at every stage of the production process.

The unwinders can run non-stop because the reels can be changed without slowing production speed and without compromising the quality or causing errors during the changeover.

Upstream and downstream machinery work in sync with the lamination machine, resulting in the ability to automate the entire process.

Above all, the automation of the nonwoven lamination process frees up workers to focus on more important tasks, while increasing at the same time the productivity of the entire plant and the quality of the finished product.